Method Statements and Risk Assessments or ‘RAMS’ should be in place before any job starts.

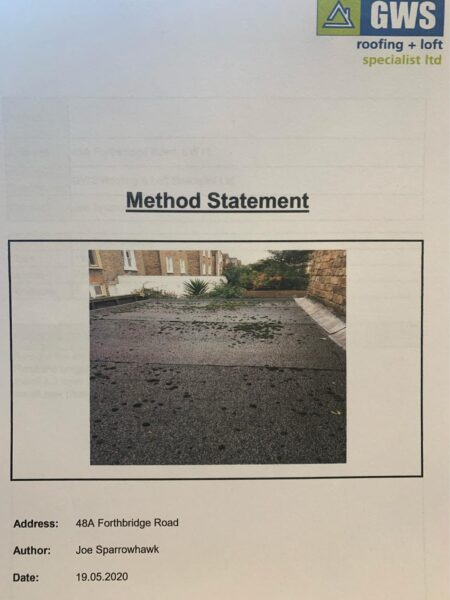

Today, one of our teams are replacing a small ground flat roof over a bathroom for a private domestic client.

Despite the jobs being quite small in size, our site manager will be meeting the guys here first thing to run through not only ‘what’ we are doing but ‘how’ we intend to do it.

The main risk factor here is that we are installing a torch on felt system so there are ‘hot works’.

The main purpose of producing RAMS is to attempt to foresee any potential problems and design them out of the job before they even start.

An example of this is organising for a self adhesive membrane to arrive for our vapour barrier (1st layer) to make sure we avoid torching against our combustible ply wood substrate.

The materials for this installation are more expensive but are in line with the NFRC’s ‘Safe 2 torch’ initiative.

So, next time you get a quote that’s cheaper…. Ask you’re self….

Can you afford to take the risk?